A high performance machines park

Only the best machines can produce first-class machining parts. We have adapted our machinery to offer them the best technical and economical solutions. We have a CNC machining center, which ensures precision machining of high quality, allowing large volumes of production and a good price. Our fleet is completed with high-precision, high-performance cam turns and single spindle lathes. To finish, we guarantee a high level of quality with our metrology service ensuring control throughout the manufacturing cycle of our parts.

Machines CNC

6 Swiss Type CNC Screw Machine

CNC Escomatic New Mach647+

This type of 4-axis machine not only allows a very fast change of series, but also the work of both spindles simultaneously, with several tools in action on each spindle. The adjustment times of these machines are rather fast, they are particularly suitable for the realization of low-cost parts in small and medium series. Machining from bars from Ø 0.3mm to 6mm. Our workshop can handle complex and usually expensive parts to machine, without unnecessary interventions from our operators.

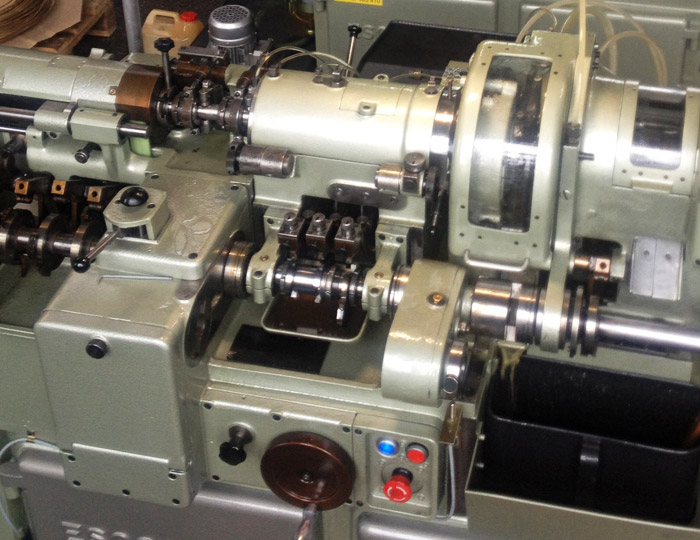

Multi Spindle Automatic Lathes

30 Tornos Swiss cam lathe with charger

Tornos T4

Traditional TORNOS T4 brand machines special fasteners for small and large series with competitive costs. This cam lathe technology is always used and mastered by our technicians while bringing the benefit of the latest technologies. Dimensions: from 1 to 4 mm All types of materials: Steel, Stainless steel, Aluminum, Brass, Copper, Bronze, plastics

Single-spindle lathe

Single-spindle lathe Escomatic D6 R

High productivity machines, equipped for counter drilling and tapping, against milling. This type of machine works all metals (steel, brass, stainless steel, copper and special alloys), from wire coils and crowns, for medium and large series, from 1 to 6 mm in diameter.

Surface treatment

Surface treatment of metals

Give us the tribofinishing of your parts (deburring and polishing surfaces) to get a precise and fast work. This industrial process combines the techniques of polishing, blasting and deburring parts and accessories. We provide the following treatments :

- Deburring

- Polished vibrator in bulk

- Black oxide or blackening

- Polishing screw heads

We also offer manual deburring, which consists in eliminating all the residual machining burrs by a manual scraping process using suitable tools.

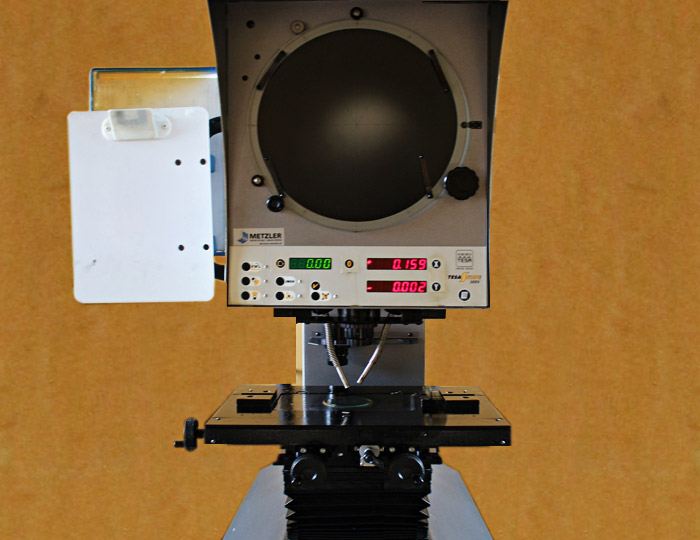

Control machines

PROFILE PROJECTOR - VARIOUS INSTRUMENT OF MEASUREMENT

TESA-SCOPE 300V Vertical Profile Projectors

In an industrial world where quality control is becoming more and more important, we ensure a control of the manufacturing using profile projectors, this type of machine is perfectly adapted to the components of micromechanics. Our measuring instrument allows us to perform a wide variety of precise measurements.